Cutting Edge Machines

Our facility and equipment utilize the most advanced technologies on the market. We’ve invested in automation and pallet systems to increase productivity and reduce setup time for repeat parts. We use modern toolpaths created using advanced CAD/CAM software to accommodate components with complex features.

Haas Universal

5-axis Machining Centers

UMC-500

- 5 axis milling

- Max workpiece 18” diameter by 19” tall

- 15,000 PRM milling

- CAT-40 Spindle

- 50 tool changer

- Tool breakage detection

UMC-750

- 5 axis milling

- Max workpiece 27” diameter by 23” tall

- 12,000 PRM milling

- CAT-40 Spindle

- 40 tool changer

- Tool breakage detection

UMC-1000

- 5 axis milling

- Max workpiece 34.5” diameter by 29” tall

- 15,000 PRM milling

- HSK-63 Spindle

- 50 tool changer

- Tool breakage detection

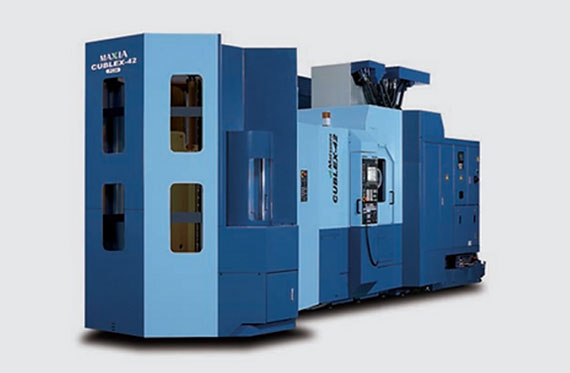

(2) Matsuura Cublex 42

- 5 axis milling and turning

- Max workpiece 16.5” diameter by 14” tall

- 20,000 RPM milling

- 3,000 RPM turning

- HSK-63 spindle

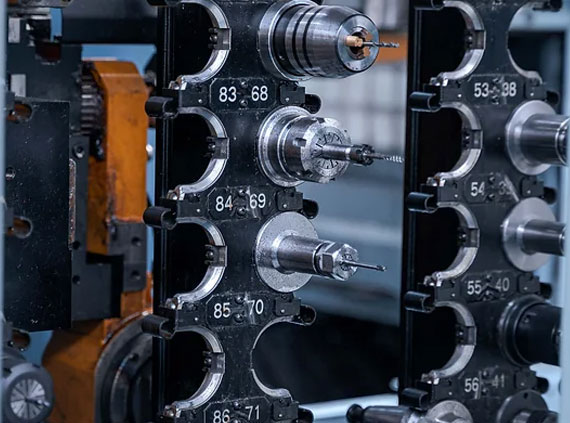

- 320 tool matrix

- 24 pallets

- Hydraulic tailstock

- Tool breakage detection

(3) Matsuura MAM72-25V

- 5 axis milling

- Max workpiece 10” diameter by 10” tall

- 15,000 PRM milling

- BT-40 Spindle

- 120 tool matrix

- 2 pallets

- Tool breakage detection

Haas Vertical

MachiningCenters

VF-3

- 5 axis milling

- Max workpiece 40″ x 20″ x 25″

- 30,000 PRM milling

- BT-30 Spindle

- 30 tool changer

- Tool breakage detection

VF-5ss

- 4 axis milling

- Max workpiece 50″ x 26″ x 25″

- 15,000 PRM milling

- CAT-40 Spindle

- 50 tool changer

- Tool breakage detection

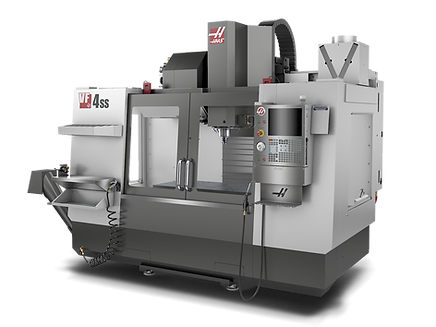

(2) VF-4ss

- 3 axis milling

- Max workpiece 50″ x 20″ x 25″

- 12,000 PRM milling

- CAT-40 Spindle

- 24 tool changer

- Tool breakage detection

(4) VF-2ss

- 3 and 4 axis milling

- Max workpiece 30″ x 16″ x 20″

- 12,000 PRM milling

- CAT-40 Spindle

- 30 tool changer

- Tool breakage detection

DM-1

- 3 axis milling

- Max workpiece 20” x 16″ x 15″

- 15,000 PRM milling

- CAT-40 Spindle

- 15 tool changer

- Tool breakage detection

Haas GR-408

- 3 axis milling

- Max workpiece 100” x 50″ x 4″

- 15,000 PRM milling

- CAT-40 Spindle

- 10 tool changer

- Tool breakage detection

AWR VBX-260 Robot Cell

- 3 axis milling

- 21.6 lbs max payload

- Up to 104 part capacity

- 8.5″ x 8″ x 8.8″ max part size

- Automated part cleaning

- Automatic soft jaw changes

Doosan Puma GT2600

- 2 axis turning

- Max workpiece 18″ in diameter by 20″ length

- Tailstock

- 10″ Chuck

- 12 tool turret

- Tool breakage detection

Haas ST-20Y

- 3 axis mill-turn

- Max workpiece 12″ in diameter by 12″ length

- 6,000 PRM milling

- 8″ Chuck

- 24 tool turret

- 2.5″ through bore